"Single pipe and double pipe series dust purifier" is the first product developed and produced by our company, representing the high-end level of the industry and leading the benchmark product of the dust purification industry!

Aiming at the smoke, a small amount of dust, peculiar smell, toxic and harmful gases produced in soldering iron, tin furnace immersion, laser marking, laser medical treatment, moxibustion beauty, chemical experiment and other occasions, it has a good purification and filtration effect. The product is suitable for point-to-point absorption of pollutants.

In these occasions, there will be a large number of harmful smoke, gas and particles. For example, different materials, additives and welding temperature will produce different moderate toxic and carcinogenic substances. This series of purification equipment is the first choice to protect the health of operators.

The product adopts multi-layer filter device, including primary filter sponge, medium efficiency and high-efficiency filter element (composed of HEPA high-efficiency filter part and gas filter part), which can make stepless and precise adjustment of air volume according to the amount of pollutants produced. It can effectively filter and intercept the polluted particles on 0.5 μ m and absorb toxic gases. The filtration purification rate can reach 99.99%. The purified clean air can be discharged directly in the room.

Overview

Quick Details

Place of Origin:Guangdong, China Brand Name:INCODE

Power:100W Filtering Efficiency:0.5μm 99.99%

Systemic Flow:260 m3/h Noise Level:<55dB

Dimensions(mm):W420×T240×H450 Weight:16Kg

Diameter of Tube:75mm Business Nature:machine manufacturer

Key words:smoke absorber package:Carton

After-sales Service Provided:No overseas service provided

Packaging & Delivery

Selling Units:Single item

Single package size:50X32X54 cm

Single gross weight:18.0 kg

Package Type:Carton

Lead Time:within 3-7 day after receiving payment

Detailed Images

Product features

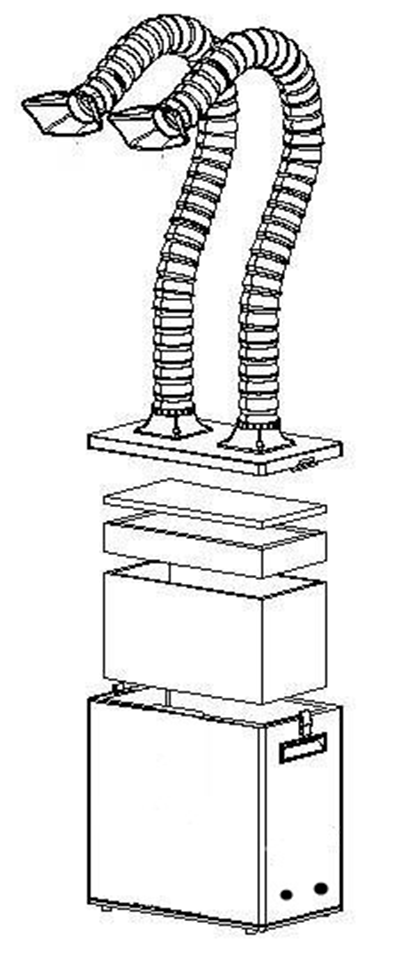

1. Appearance and structure

◆ simple and elegant appearance, steady and elegant. Integrated design, metal frame structure, high-quality cold-rolled steel electrostatic spray process, durable. Simple, economical and practical. ◆ both sides are equipped with high-quality plastic handle, which is delicate, stable and reliable, and easy to handle. The unique modeling curve design of the air inlet flange is more in line with the principle of fluid dynamics. ◆ install humanized stepless governor, and adjust the air volume and suction at will. ◆ the product is small in size and does not need to be installed, which is conducive to clean and beautiful working space and convenient to move. 2. fans

◆ it adopts the form of DC brushless motor and built-in controller, with more guaranteed performance and quality. ◆ stable operation, low noise, high efficiency, low energy consumption and long working time. No need for regular maintenance, lower cost. ◆ the wind wheel adopts eddy current backward design and special alloy material, effectively preventing the wind wheel from corrosion. The unique dynamic balance correction technology makes the wind turbine run more stable and reliable. High air volume, large suction, higher filtration rate. 3. Filtration system

Adopt quadruple filter design. Filter layer by layer to ensure that harmful smoke and dust are filtered more thoroughly. The purification rate can reach 99.99%. ◆ modular design, layer by layer protection. The primary, middle and high efficiency can be replaced separately, the service life of filter element is longer, and the replacement cost is lower. ◆ the unique internal sealing structure and special sealing materials enable all harmful substances to pass through the filtering system with higher filtering efficiency. ◆ the built-in circulating active filtering mode avoids discharging the indoor air conditioning / heating out of the room, and does not damage the temperature and humidity environment in the operation area. 4. Smoke collection device

◆ the machine is equipped with universal smoking arm, which can change direction and position at will (the length can be customized according to customer requirements). The end is equipped with a new type of smoke collecting hood, which has unique shape and higher smoking efficiency. ◆ simple installation, convenient use, no need to lay additional pipes.

Working principle

The purification equipment adopts physical active purification and filtration. The pollutants are inhaled by vortex centrifugal fan. After purification by multi-layer filtration device, the clean air is discharged directly in the room.

Fault phenomenon and maintenance

Due to the high voltage and strong current inside the equipment, please cut off the power supply before checking and maintaining the equipment!

Non professional personnel are strictly prohibited from dismantling the equipment. So as not to cause safety accidents.

1. Fault phenomenon:the system is still working and the noise is increasing, but the air volume is weak and the suction force is greatly reduced.

Possible causes:

① the air inlet or air outlet is blocked

② Clogging of filter element due to saturation failure

Treatment: turn off the power supply, open the top cover, check whether there is foreign matter blocking the air inlet, and then check whether the air outlet is blocked.

If there is no difference after inspection and treatment, restart the machine. If the air volume is still small, replace the filter element.

2. Fault phenomenon: after the machine starts, it will shut down automatically, turn on again and repeat the above phenomenon.

Possible causes: the internal air flow is blocked, the filter element resistance is too large, resulting in the fan starting current is too large, and the system automatically protects and shuts down.

Treatment method: turn off the power supply, open the top cover, and check whether there is any foreign matter blocking the air inlet; if there is no abnormality in the inspection and treatment, adjust the air volume knob to the minimum, and then restart the machine, and adjust the knob to the appropriate air volume position.

3. Fault: the equipment does not work.

Possible causes:

① the power switch on the back of the machine is not turned on

② Fuse in the three in one switch is blown

③ The knob of operation panel is not opened in clockwise direction

Treatment:

① check whether the power cord is plugged in properly and whether the red switch on the back is pressed down

If the red light on the back is on, it means that the equipment is powered on normally. Turn on the front knob again. If the green indicator light is on, it means that the circuit control of the device is faulty. Please contact the manufacturer at this time

② If the back red light is not on, take out the fuse in the three in one switch to see if it is burnt out

If the fuse is blown, replace the spare fuse and switch on again.

Company introduction

Guangzhou INCODE marking technology co., ltd. its a high-tech enterprise ,founded in 2008, we provide the most professional industrial inkjet service and also the various type of marking equipment, For example the Continuous Inkjet Printer,Tij Inkjet Printer,Laser Marking Machine,UV printer,Egg printer,Conveyor Belt,Paging machine,Inkjet Spare Parts ,SMOKE PURIFY MACHINE etc.

We have more than ten years of specializing in printing technology research experts, have many years of industry marking machine distribution and after-sales service and maintenance experience, has a technical mastery and responsive, service first-class professional team, can provide customers with various types of machine in all aspects of professional technical services and high quality professional consumables, to provide customers with mature and reliable industrial printing solutions.

We are committed to "becoming the most professional industrial inkjet code service provider" based on service and quality.