Laser cleaning equipment is a new generation of high-tech products for surface cleaning. Easy to install, operate and automate. Open the equipment, you can clean without chemical reagents, medium, and water. It can remove resin, oil, stain, dirt, rust, coating, plating, paint, etc.

a. Non-contact cleaning, without damaging the part matrix.

b. Precise cleaning can achieve selective cleaning with precise location and precise size.

c. No chemical cleaning fluid, no consumables, safety and environmental protection.

d. The operation is simple, just power on, and it can be hand-held or cooperated with a manipulator to realize automatic cleaning

e. The cleaning efficiency is very high, saving time.

f. The laser cleaning system is stable, almost no maintenance.

Overview

Quick Details

Condition: New; Power: 3200W

Applicable Material: Acrylic,Aluminum,Metal; Marketing Type: New Product 2020

Core Components: PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear Pump;

Laser Type: Fiber Laser; Place of Origin: Guangdong,China

Brand Name: INCODE; Dimension(L*W*H): 1100mm×700mm×1150mm

Laser Source Brand: RAYCUS; Laser Head Brand: RAYCUS

Weight(KG): 290KG; Product Name:IN-LC300W

Scan Width: 10-80MM; Fiber Power: ≥300W

Cleaning Efficiency: 15 m2/h; Power Adjustment:10%-100%(Gradient Adjustable)

Center Wavalength: 1064nm±5nm; Warranty:Up to 2 years

Packaging & Delivery

Packaging Details:Wood Case

Port:Guangzhou or Other Port

Image Desciption

Product Parameter

A.Laser Cleaning Machine Operating Parameters

Table 1 Basic operating parameters of equipment

Content | Parameter |

| Supply Voltage | Single-phase 220V±10%, 50/60Hz AC |

| Power | 3200W(With Chiller) |

| Place the Environment | Flat, No Vibration,No Impact |

| Working Temperature | 0℃~40℃ |

| Working Humidity | 30%~80% |

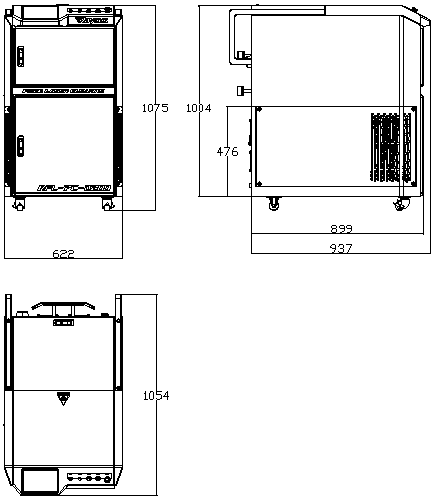

B. Laser Cleaning Machine Mechanical Parameters

Table 2 Equipment mechanical parameters

Content | Parameter |

| Size | 1100mm×700mm×1150mm |

| Weight | 290Kg |

| Fiber Length | 5m |

| Washing Head Weight | 3.0Kg |

| Move Method | Hand Held |

| Scan Width | 10-80mm |

C.Optical Parameters of Laser Cleaning Machine

Table 3 Equipment optical parameters

Content | Parameter |

| Average Laser Power | ≥300W |

| Output Power Instability | <5% |

| Power Adjustment Range(%) | 10-100(Gradient Adjustable) |

| Pulse Width(ns) | 130-160 |

| Center Wavelength(nm) | 1064±5 |

| Repeat Frequency(kHz) | 25-50(Gradient Adjustable) |

| Maximum Single Pulse Energy(mJ) | 12.50 |

| Maximum Peak Power(kW) | 96 |

| Fiber Core(μm) | 100 |

| Cleaning Efficiency(m2/h) | 15 |

| Focal Length(mm) | 100/160 Replaceable |

| Cooling Method | Water Cooling |

Product Structure Diagram And Apearance Diagram

Laser Cleaning Technology Application

Laser cleaning is currently widely used in industry. It is mainly used for rust removal, paint removal, oil removal and oxide film removal of precision parts. Due to its high efficiency, energy saving and environmental protection, it is used in molds, automobile manufacturing, cultural relics restoration and shipbuilding. And other industries are popular.

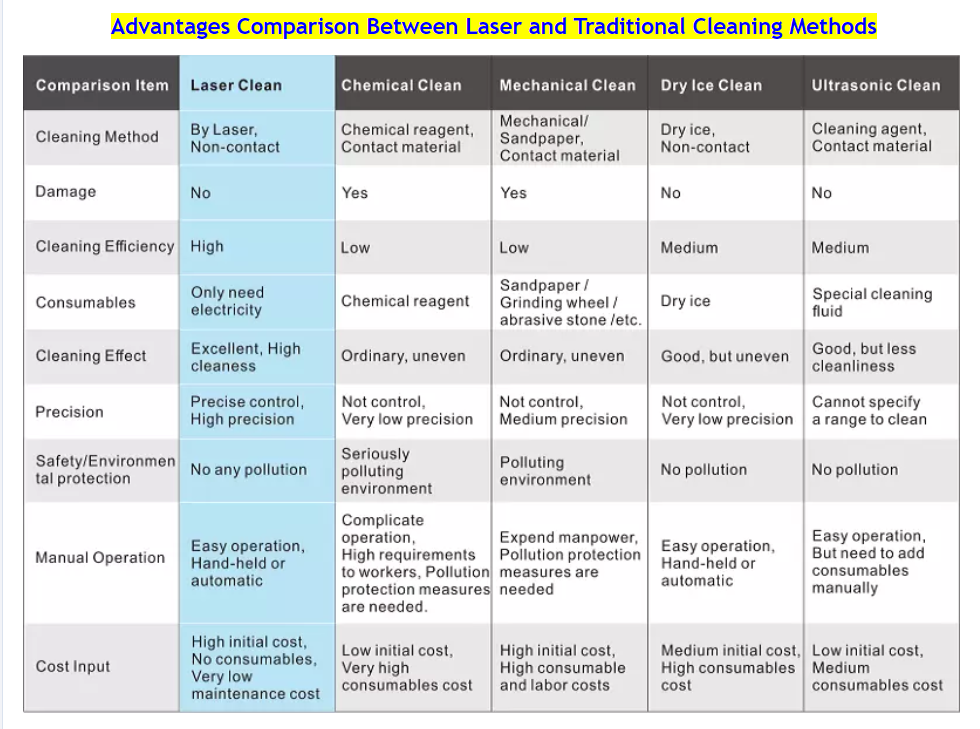

Advantage Comparison

Company introduction

Guangzhou INCODE marking technology co., ltd. its a high-tech enterprise ,founded in 2008, we provide the most professional industrial inkjet service and also the various type of marking equipment, For example the Continuous Inkjet Printer,Tij Inkjet Printer,Laser Marking Machine,UV printer,Egg printer,Conveyor Belt,Paging machine,Inkjet Spare Parts ,SMOKE PURIFY MACHINE etc.

We have more than ten years of specializing in printing technology research experts, have many years of industry marking machine distribution and after-sales service and maintenance experience, has a technical mastery and responsive, service first-class professional team, can provide customers with various types of machine in all aspects of professional technical services and high quality professional consumables, to provide customers with mature and reliable industrial printing solutions.

We are committed to "becoming the most professional industrial inkjet code service provider" based on service and quality.